Enter the email address you signed up with and well email you a reset link. Log in with Facebook Log in with Google.

Mechanical Design Of Heat Exchangers

Traditional heat exchanger design methodologies largely rely on highly empirical fixed TEMA fouling factors TEMA 1941These are basically safety factors that lead the designer to specify an oversized heat transfer area that in theory should compensate for reduced thermal efficiency caused by fouling.

. The design of earthair heat exchanger mainly depends on the heatingcooling load requirement of a building. A heat exchanger is a system used to transfer heat between two or more fluidsHeat exchangers are used in both cooling and heating processes. 1 the design of the shell and tube heat exchanger needs to be.

Many stainless steel tank fabricators are asked to build ASME pressure vessels every day. Place a 1 ball valve between the isolation valves and the heat exchanger on both the supply and return. The mechanical design of a shell and tube heat exchanger provides information on items such as shell thickness flange thickness etc.

Heat Exchanger Cleaning Procedure. Thanks to the automated production and compact design of our brazed plate heat exchanger series we can put together an individual heat exchanger for you within a very short time. Cook J ed.

We fabricate ASME flanged and dished tank heads that will meet the needs of your business and your customer. Design and application In principle all of our plate heat exchangers function similarly. Close Log In.

These are calculated using a pressure vessel design code such as the Boiler and Pressure Vessel code from ASME American Society of Mechanical Engineers and the British Master Pressure Vessel Standard BS 5500. USE CODE DH1 AT CHECKOUT AND GET 100 off ON ANY. Run ice cold intercooler temps with our Killer Chiller heat exchanger designed to piggyback the vehicles AC system.

αRatio of heat transfer area on one side of a plate exchanger to total volume between the plate on that side. The Business to Business Web Search Engine - OPENFOS is a leading Business search and directory serving the US B2B community. Founded in 1923 Aerofin is a leading manufacturer of finned tube heat exchanger coils and related heat transfer equipment and accessories such as process gas coolersheaters transformer oil coolers fancoil units face and bypass coils frames for coil removal capabilities airside transitions and drain pans.

After the 2003 addenda of ASME Code Section VIII Div. FBM Hudson Italiana design and manufacture all types of Shell Tube Heat Exchangers either according to classification as per TEMA. Heat Exchanger Design Handbook.

The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. The Killer Chiller system is a specially designed refrigerated heat exchanger using a plate to plate design one of the most efficient heat exchanger designs on the market. Article Google Scholar Labs K 1989 In.

Tube tie rods and spacers transfer baffles or support plate impingement baffle floating head flange and. The welding team joins the required manifolds flanges as well as components to the core of the heat exchanger. VPE carefully cleans and tests the heat exchanger to verify it is leak-proof.

Kanaris AG Mouza AA Paras SV 2006 Flow and heat transfer prediction in a corrugated plate heat exchanger using a CFD code. Paul Mueller Company specializes in the design and manufacture of stainless steel processing systems equipment for a wide range of industries. ASME code heads are required in a wide range of processing industries to ensure safety and quality standards are a top priority.

Zip Code City. 10841360158 Indirizzo PECRegE-mail address. In shell and tube heat exchangers there is a potential for a tube to rupture and for high pressure HP fluid to enter and over-pressurise the low pressure LP side of the heat exchanger.

A company incorporated in 1974 as manufacturer of fully welded plate heat exchanger and high-pressure vessels internals for chemical. Remember me on this computer. Our world-class team together with leading metallurgists and major specialists is extremely capable of resolving your most challenging corrosion application mechanical or thermal design issues.

VPEs diffusion bonded microchannel heat exchangers are U or UM stamped and meet the requirements of the ASME Boiler and Pressure Vessel Code. Besides avoiding heat exchanger failures with RYDLYME you regain original design heat output efficiency and reliability. Depending on the purpose for which the heat exchanger is needed they may differ in configuration structure and materials used.

The Heat Exchanger Inspection article provides you with information about the inspection and testing of. βThe ratio of the heat transfer surface area of a heat exchanger to its volume is called the area density. Isolate and drain the water-side of the exchanger to be cleaned.

Chem Eng Technol 8923930. Our brazed plate heat exchangers offer customized solutions for a wide variety of applications. One million US manufacturers wholesale resellers contractors and service companies lists within.

They are widely used in space heating refrigeration air conditioning power stations chemical plants petrochemical plants petroleum. The cylindrical design of the housing is extremely resistant to pressure and allows all ranges of pressure applications. Please contact us by phone at 805 487-5050 or toll-free at 877 487-5050.

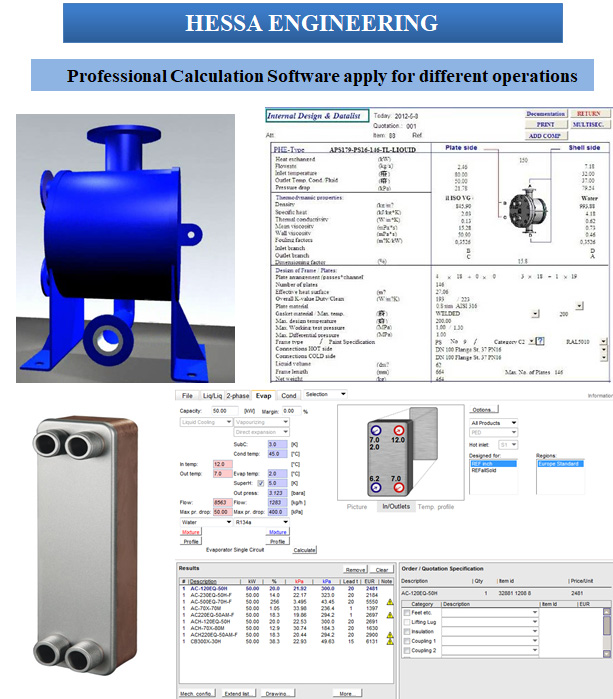

Plate Heat Exchanger Engineering

Tl6 Plate Heat Exchanger Alfa Laval

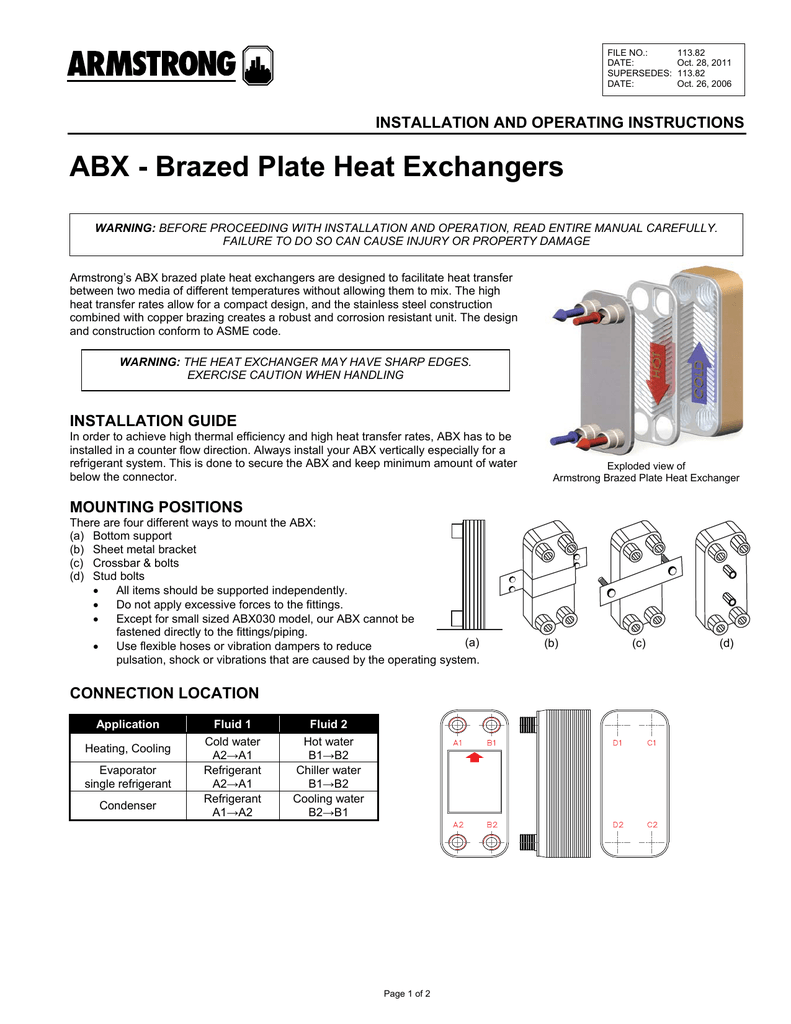

Abx Brazed Plate Heat Exchangers

Pdf Plate Heat Exchanger Selection Sizing And Troubleshooting Kolmetz Handbook Of Process Equipment Design

Basic Dimensions Of The Gasket Plate Heat Exchanger Download Scientific Diagram

Plate Heat Exchanger Matlab Simulink Model Youtube

Module 118 Right Sizing Brazed Plate Heat Exchangers Cibse Journal

0 comments

Post a Comment